Flax to linen

-

Getting started

This box is about 4’ x 4’ and it usually houses vegetables, but this summer it is going to be the home of my flax plants. I bought some real linum usitatissimum seed and planted it today, April 19.

-

Baby plants

I know some squirrels that consider my garden to be quite their own, so a few of my baby flaxes have been disturbed/dug up. I put fresh seed in but we shall see; the sparrows have also asserted territorial rights over my plantings, and they do like flax seeds. It’s May 15.

-

June 3

They’re getting to be tweens now. So far the squirrels are behaving themselves; I guess they have found greener pastures by now.

-

June 5

We have had a tremendously wet spring and the plants are very happy; see how they grow!

-

June 23

The blooming has begun! It feels strange to me to think that I won’t allow the plants to mature completely. The idea is to harvest them before they have lived their full life cycle. If I wait until the seeds are all ripe and the plants are brown, the quality of the fiber won’t be great. Tough flax makes tough linen, I guess.

-

July 16

We’re getting close. When the bottom third of the plants is brown, it is time for harvest. Most of the flowers have gone to seed, but it is still immature. I do have a few plants that are blooming - these likely grew from the second, post-squirrel-digging, seeding.

-

So pretty

-

july 21

I think today is the day! Most of the seed heads are yellow and the plants are looking tired. I’ll wait until afternoon so the dew is off of the plants.

-

back to square one

30 minutes and 10 dirty fingernails have wrought this change. We had an unscheduled downpour late this morning, but things dried up enough, I hope, for the harvest to be a success.

-

one pile

I’ll let these guys dry in the sun this afternoon and then I’ll wrap them into bundles and keep them in the garage overnight.

-

more flax

I think I’ll keep bringing my friends outside on dry days and letting them sleep overnight in the garage until the seed heads look nice and dry. I am hoping to harvest as much seed as possible for next year’s crop.

-

and more flax

After the flax is nice and dry and I’ve removed the seed heads, I’ll ret it. I have some big rectangular plastic planters that should work well as vessels.

-

bonus nettles!

My neighbors have a rather wild yard and these beasties were leaning into our yard, so I put on some thick gloves and snitched them. I consider it a public service, as nettle is a terror that burns the unwary passerby. They are twice as long as my gentle flax, so if I can extract their fibers, it will be a happy day. —P.S. I have done some research, and the happy day will have to wait until next year; the nettles need to be used fresh. Something to look forward to!

-

rippling without a rippler

If I ever grow more flax than I did this year, I'll build myself a rippler. But for this amount, my fingers and I were okay with removing and squashing the seed heads by hand. I'll winnow the seeds and plant them next year. And, oh my, the flax smells sweet!

9/15/24

-

time to ret the flax

I can't use my old plastic window boxes this year; I bought some new and particularly spunky seed this year, and got very tall plants that were too long for my old boxes. So I had to get a new retting bin; it's close to 4' long.

-

retting day 0

I covered the flax with water and then weighed it down with some bricks. The weather is very warm, mid-80s, this week, and no rain is forecast, so I'm expecting this process to go fairly quickly.

9/15/24

-

retting day 1

After the first 24 hours and 87 degrees F, the water is yellow, but it smells really good! I bailed out about 3/4 of it and then re-covered the flax with fresh water. This will, I hope, keep things from getting overly rank. If I had a stream to ret the flax in, it would be getting fresh water continuously; this is my approximation.

9/16/24

-

retting day 2

Foamy! After 48 hours, it doesn't smell so good, but it's not super stinky; we are at 86 degrees F. Once again, I bailed out a bunch of water and then refilled the bin with clean water.

9/17/24

-

a test

It's too early for the flax to be ready, I know, but I wanted a benchmark. The plants are still quite stiff and this one didn't open easily, but there are a few loose hairs in there already!

-

day 3

Yes, yes, the Dead Marshes, that is their name. No elves, humans, or orcses, but this little swamp is busy with decomposition. After 72 hours we are chugging along. It is 84 degrees today and I'm thinking that this flax is not going to take the usual 7-10 days to break down.

9/18/24

-

another test

I've been reading about retting and was horrified to see in one article that lime in water prevents retting (1). We have very limey water in my city thanks to a water-softening project that was implemented a couple of years ago. But this flax does seem to be coming apart nicely.

-

day 4

We're at 96 hours now and I'm starting to think that the dire warnings about Limey Water don't apply in my case. It's 83 degrees F and after four very warm days, the flax is getting close to being cooked. The water is actually bubbling, which is cute.

9/19/24

-

another test

Am I making a mistake? This looks pretty good to me. Maybe the age-old adage, "don't over-ret" leads the uninitiated to the well-worn plaint, "I didn't ret this long enough". I will give it one more day and then take it out. Maybe.

-

day 5

At 120 hours, it is 81 degrees F and this stuff officially stinks.

9/20/24

-

last test?

Even the thickest stalks are more than willing to collapse and show me the threads inside. I think I'll call this done.

-

I'll wear gloves next time

Whew, this guys don't smell like they did when they went in. I'm still wondering if I left them in the water long enough, but I figure that it will be less of a disaster if I under-ret them than if I over-ret them. I can always put them back in the water later, if necessary.

-

maybe they'll dry here

My seven bundles look like this with their hair down. It is not supposed to rain for the foreseeable future, so I am going to leave my friends out here by the aging garden for a few days. I'll turn them over every morning.

-

but not this morning

We had thunderstorms all morning. When the sun comes back out, I'll stand my poor, bedraggled flax against a wall or something.

-

it's drying!

I didn't have to pick it up; it is drying nicely on the ground. It has been there for three days now, with no real attention from me other than that I turn it over every morning and tidy up the plants that the birds have tried to drag away. Research on how to make scutching, breaking, and hackling devices has begun.

9/22/24

-

an experiment

I broke off the outer shell of this flax stalk with my hands, just to see how hard it would be to free the fiber beneath. It wasn't hard, and it looks like the fibers are still intact, all good news, though there is quite a bit of boon (bits of outer stalk) left to be picked off. I suppose this might have been an early method for getting at the fibers?

-

We have everything we need

At least, I have everything I need for the first step of the process.

-

but what is the first step?

I have checked with several sources, and while the order of operations seems to vary, the steps themselves seem to be pretty consistent.

Elizabeth Barber, an expert on ancient textiles, says that flax was historically processed by 1) breaking the fibers, 2) scutching the fibers (thereby liberating the flax from the boon) and then 3) hackling or combing the fibers (2).

The book Linen: From flax seed to woven cloth provides the same order. (3)

An instructional video from a teaching farm in Ireland gives this order: : 1) scutching, which the docent calls "breaking down the fiber"; 2) breaking (which he calls "crimping"); and 3) hackling (which he calls "brushing"). (4)

The flax, by the way, has returned to its sweet-smelling ways. And I don't think I killed any of my plants by watering them with anaerobically infused water.

-

my procedure

1) scutch: I don't have a cool wooden knife to use, but I do have a piece of 1"x2" pine, about 18" long, and an old board that used to be a shelf but hasn't had a job in a long time, other than collecting dust in the basement. The goal of this scutching will be to clean as much dried mud and junk off of the stalks as possible and to begin the breaking down of the outer part of the stalks.

2) break: I'll have to make a tool for this step. I'm going to try to replicate the tool in the first video listed above. It kind of reminds me of a tortilla press, but instead of squashing the flax flat, it will catch it between long, skinny boards and break up the outer stalks.

2.5) If I need to return to the scutching to scrape off more of the outer stalk, I will do that!

3) hackle: This is where we comb out all of the rest of the boon from the flax hairs and also where we separate the long (line) from the short (tow) fibers. We? I'll have to make a tool for this, as well.

-

makeshift scutching board

Here is the board that used to be a shelf, somewhere. I padded the top with an old towel and braced the bottom with my foot to keep it steady while I used the piece of 1"x2" wood that I cut a couple of frames ago to whack the flax.

-

I can see why this can be called breaking as well as scutching

I found that if I hold the flax over the board like so, I can break it pretty easily.

-

the root ends

I am getting more mileage out of hitting the root ends than the bloom ends of the plants - the whacking (my name for this step) gives more results on these thicker, tougher, and stiffer parts of the plant. The top parts just bend and don't break.

-

whacked flax below, unwhacked on top

I feel like I'm getting the hang of this, but the biggest result seems to be that the flax is getting cleaner and that I'm getting started breaking up the outer shell.

9/24/24

-

next step: break or crimp

I am going to try to make something that looks like the crimping tool used in source (4), but without the stand. I am reusing more old wood here. I cut two 12" base pieces from an old 2"x4".

-

next layer

On top go a couple of 1"x2" pieces, about 7" long.

-

the business pieces

More 1"x2" pieces, all more or less 24" long. The first, third, and fifth will be screwed down to the base pieces and the second and fourth will act together as the moving part.

-

handle

I don't think I have an old handle, so I might just put another piece of wood on top of this. Now I need to take a trip to the hardware store for some . . . hardware.

-

Sources

(1) Martina König, "Flax fibre extraction techniques in the late Middle Ages," EXARC.Net, "Retting" section.

(2) Elizabeth Wayland Barber, Prehistoric textiles. Princeton University Press, 1991, p. 13.

(3) Linda Heinrich, Linen: From flax seed to woven cloth. Schiffer Publishing, 2010, pp. 27-32.

(4) https://www.youtube.com/watch?v=TFuj7sXVnIU

9/27/24

-

crude. effective?

I got it drilled and screwed together (other than the handle) this morning and it is a bit wonky, but I think it will do the job.

-

It works!

I am starting to suspect, though, that I should have retted my fibers a bit longer. There is still quite a lot of hard shell around my linen fibers, even after this extremely brutal process.

-

first batch

There's some nice linen in there. I think that "step 2.5" will be necessary, however, as there is so much boon still sticking to my fibers. I am afraid that if I try hackling it, the fibers will tear. I am going to stick with this tuft and see it through to the end of the process, and then go back and re-ret the other fibers if I think it prudent.

9/29/24

-

I broke down

And I retted the rest of it again. I figured I only have so much time this fall to get this done, because I want to play with spinning it during the winter. It was a chilly week and I left the flax in the tub, no water changes, for six more days.

-

all done, again

Here it is, drying out. I plan to leave it in the garage for about a month, so that I can be sure that it is good and dry.

-

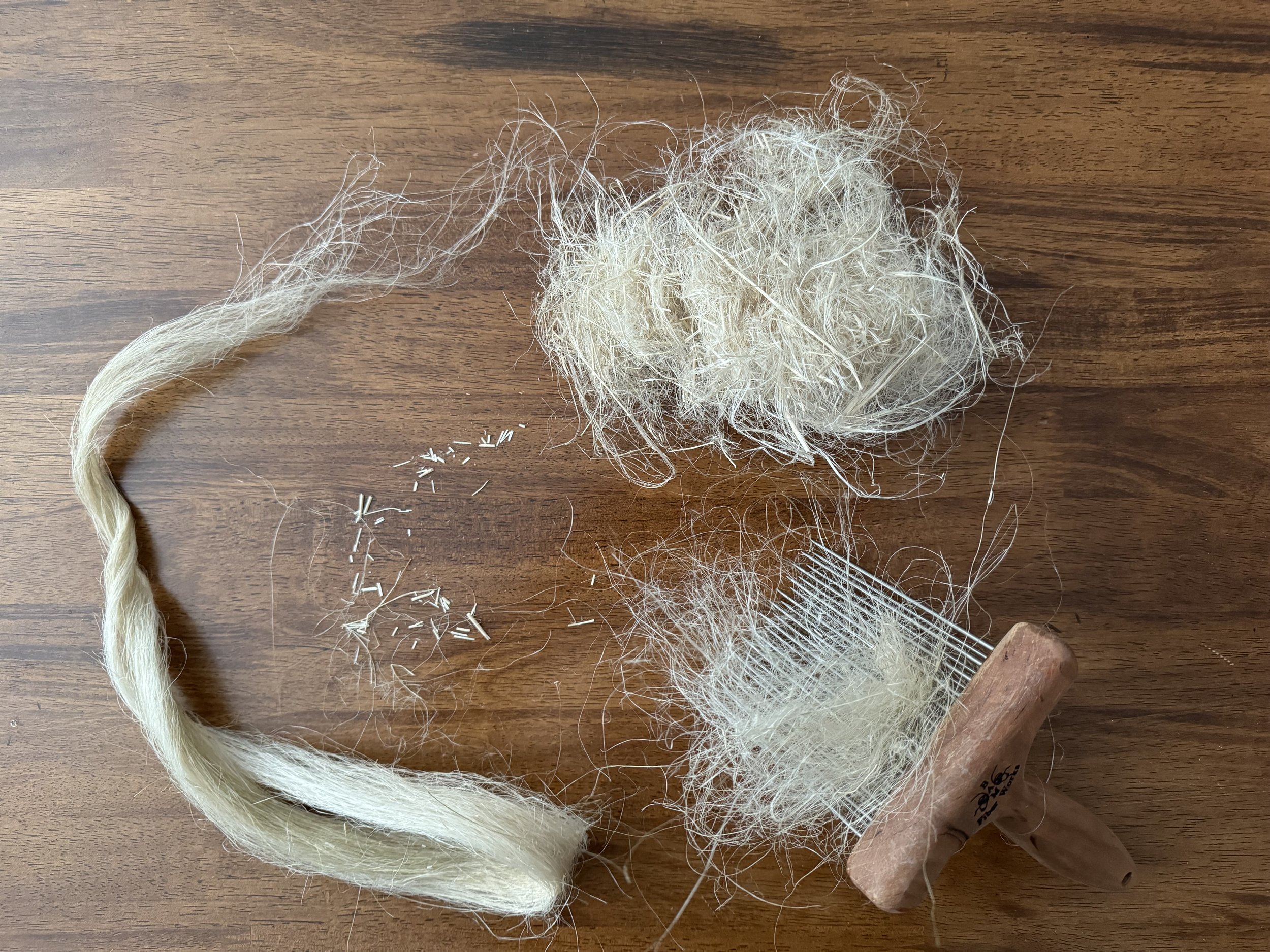

back to the first bunch

I decided to try “hackling” my flax with my wool comb, heathen that I am. It worked quite well, though I do suspect that I broke off more of the line flax than I would have, had the retting process been more complete. Just a guess.

-

still some boon

If you zoom in, you can see that there is still some boon in my lovely linen fibers. I am hoping that another round with the wool comb will take more of that out. I have also tried a surely unorthodox shimmy with it, holding an end in each hand and sort of rocking it back and forth. The fibers seem to be strong enough to endure this rather rough treatment.

-

more combing

At some point I will give up and try spinning it, but it would be really nice to get it clean first. I tried combing the tow with both wool combs, and I thing that I should be able to get it fairly clean, as well.

-

lots of tow, a bit of line

But oh, that line is beautiful!