a big project, Part I: weave and full

-

what is a big project?

That is what my Uncle Bill used to say when he saw someone bite off more than they could chew. I’m planning to weave this undyed Shetland wool into a twill fabric, dye it, and then sew with it. I am considering making a medieval kirtle, though I might just make some pants.

-

too scared to start here

This is my first Big Project, so I am not going to start with the spinning of the wool. Next time, though!

-

we begin

My goal is to have 832 + 4 floating selvedge warp threads. 98 so far.

-

Weaving yarn

This yarn is super-active! It springs back on itself when I pull it off the skein. I guess all of that energy will come in handy as it’s warped onto the loom.

-

868 threads

I hope. I decided to use a few more threads in the warp than I originally planned; I’m thinking that the fabric will shrink a fair amount, width-wise, when I finish it. I want it to be at least 20” wide when it’s all done.

-

Ready for heddles

I don’t have enough heddles to use single strands, so I’m going to use double strands; I’ll also use two strands in the warp. The fabric will be thicker, but that is just fine.

-

Lovely!

The thread counts did come out even, and I have two extra threads on each end for a floating selvedge - they aren’t threaded through heddles, just through the reed. When I weave right-to-left, I pass the shuttle over the floaters and when I weave left-to-right I pass it under them. A nice selvedge ensues.

-

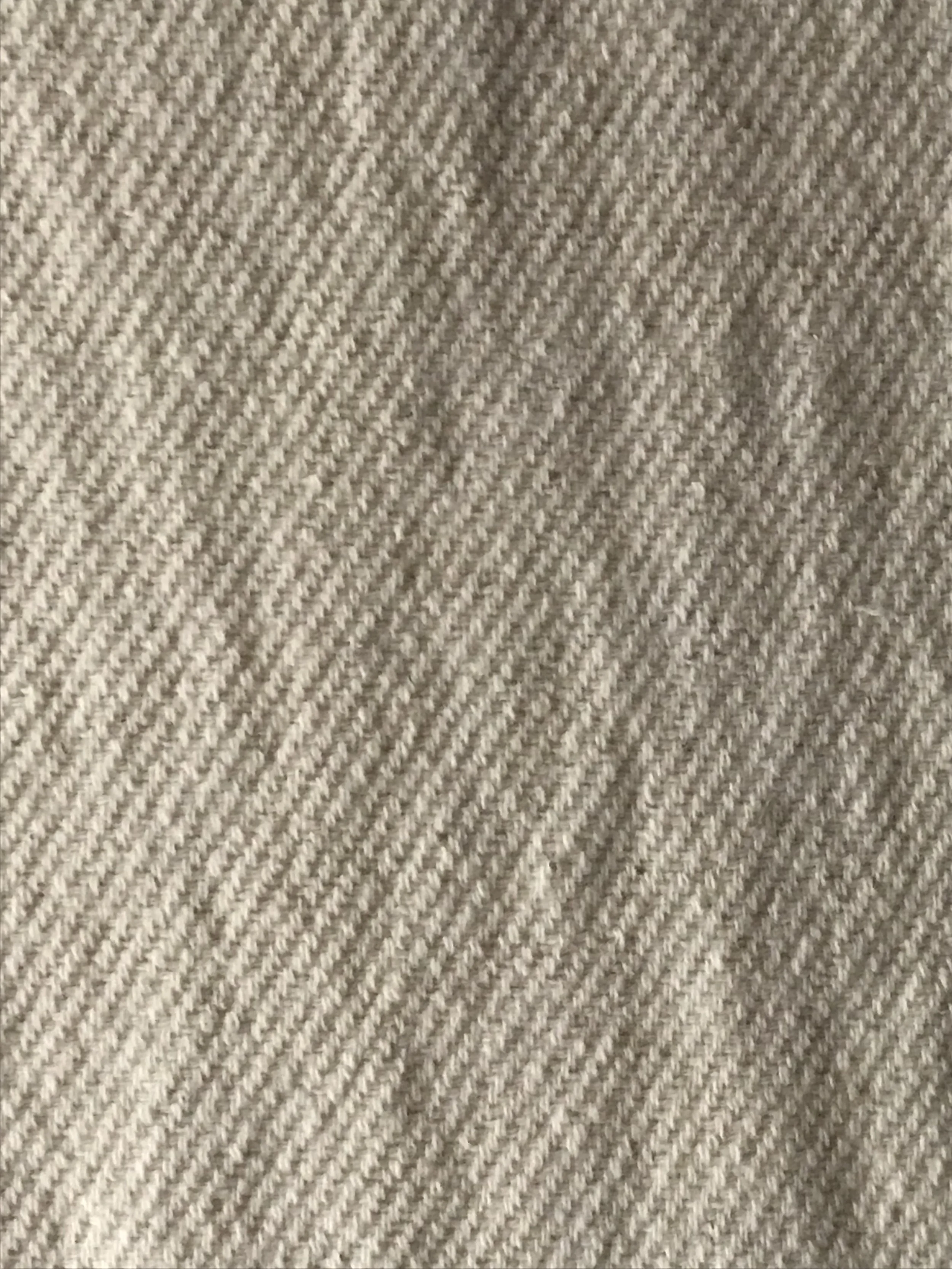

Twill!

This is some sticky wool, for sure, and see how beautiful it is!

-

a tight warp thread

Can you see the wavy weave I’ve got going? That’s because this sticky wool is sticking to itself behind the heddles, which is causing the fabric to pucker.

-

the culprits

The threads are clumped up behind the heddles. The fix is quite simple - I just have to ease them apart. Once everything is moving freely again, I’ll be on my weaving way.

-

loose warp threads

A pair of warp threads was sagging, so I pulled them into a little loop. When I’m done weaving, I’ll fix this up nice.

-

a homemade heddle

That green heddle is made out of crochet cotton. I made a mistake when I was threading my heddles; instead of threading 1-2-3-4-5-6-7-8, I threaded 2-2-3-4-5-6-7-8. So I just pulled the warp out of one of the two 2s and made a new 1 heddle.

-

here's how

I cut a thread that is about 4” longer than the heddle needs to be. I loop that thread under the shaft where I want the heddle to be.

-

first knot

I tie the first knot (overhand) at about the same place as the bottom of the opening on the other heddles.

-

second knot

The second knot (also overhand) goes at about the top of said opening.

-

third knot

The last knot goes over the top of the shaft. This one is a square knot.

-

and there it is

No more stress about missing counts on heddles — as long as the number of warp threads is correct, you can make as many makeshift heddles as you need.

-

fabric!

I think I’m about a third of the way done. My front roller is getting a bit full already, so I might have to cut off some of the finished fabric and reattach the warp. I’ll cross that bridge if I come to it.

-

keep your warp happy

Words to live by. See that vertical line in the middle of the photo? The warp is jumping over three weft threads, not the sanctioned two.

-

the cause

I’m pretty sure that those crossed heddles (sorry about the fuzzy foto) are the reason. I advanced the warp a bit and then combed it out, which seemed to fix the problem.

-

and keep your threads tidy

Of course, I did have to pull out the weft, un-weaving a few rows. Not the first time!

-

no problem here

When you weave a 2x2 twill with your threads doubled, every little packet of warp threads has four threads in it. When the sheds are changed, the lowered packets of warp thread rise and these upper packets sink down.

-

we like this look

As I beat, each warp at the fell line (that is, the last row of weft woven) has a short and a long pair.

-

problem here

In the middle of the photo, one little packet has six warp threads instead of four. This happens if I pick up threads from a lowered packet of warps.

-

something to fix

Just right of center, there is an irregularity at the fell line. The warp from two picks down is budging. That’s because I picked up a couple of warps from the lowered packet. On purpose, of course.

-

what is this?

I have a strange bump going here. I’m not sure what it is, but I’ll advance the warp a bit and take a look. Oh! I also have another boo-boo there a few picks below the bump!

-

reason found

The problem wasn’t at the back of the heddles this time; some threads just got themselves hooked together at the front of the reed. A quick pat separated them and I was back in business.

-

that's a lot of fabric

It’s amazing to think that one can create such an enormous thing with such slender materials, one throw at a time. Someday I’ll calculate just how many picks are in this fabric

-

this also happens a lot

Instead of my nice, open shed, I often find stray warp strands creeping all over the place. The shuttle would have a stress attack if it tried to make its way through that maze.

-

behind the reed

Here is where the problem, and the solution, both lie. Isn’t it nice when you can find and solve a problem all in one go? Some of the wool threads are acting woolly, and are clinging to each other in this liminal space between the heddles and the reed. It is clear here whether they need to be up or down, it is easy here to separate them, and we are back in business.

-

when a warp thread breaks

I had two broken warps on the first day I wove and none since, but here is a lovely loose thread (the knot kept catching on the reed when I beat and it stretched the wool). We’ll pretend that it is about to break.

-

oh whoops, it broke!

Okay, I cut it. The loose end at the bottom just got more or less pushed aside. This end will have a new thread tied on.

-

what we need

I took a too-long bit of thread and a T-pin. That’s my loose warp end wandering off to the left.

-

first I tie a new knot

One end of my new thread gets tied to the broken end. It’s easier to tie if you are not as close to the reed as I am here. I could have advanced the warp if the knot proved impossible, but it was not.

-

all tied up

I stuck the T-pin into the fabric at the right of my warp target, wrapped the thread around once, stuck in the T-pin at the left of my target, and then did a fancy figure 8 around both ends of the pin.

-

then just weave

Here it is a few inches along; you can see the knotted part still waiting to be woven, but it is behaving much better than the previous knot did. I can remove my T-pin now. No worries about anything slipping, especially with this wool.

-

hold my hand, I'm still weaving

It’s a bit fuzzy, but maybe you can see that the reed/beater is bumping into the roll of fabric on the front roller. This means that my weaving area is gradually shrinking, but I am getting really close now to the end of the warp; I don’t want to cut off my fabric and retie the warp at this late date.

-

close!

I think the warp is getting tired. I think I’m getting tired, too. I only have a couple more feet to go. I did run out of my wool - I seem to have exhausted the inventory of my seller and can’t get more - but I have some thinner wool that seems to be working fine.

-

loose

I cut it free from the warp - I had another 10” or so of warp available to weave, but the front roller was bumping against the front beam and I couldn’t turn it easily. I figured that was a sign that it was time to be done.

-

The next step is fulling

I’ve been doing a bit of research on fulling and it seems that I have several choices as far as methods and materials go. One thing for sure is that I need to clean this fabric! By the way, I ended up using a whopping 18,000+ yards of yarn for this 6 yards of fabric.

-

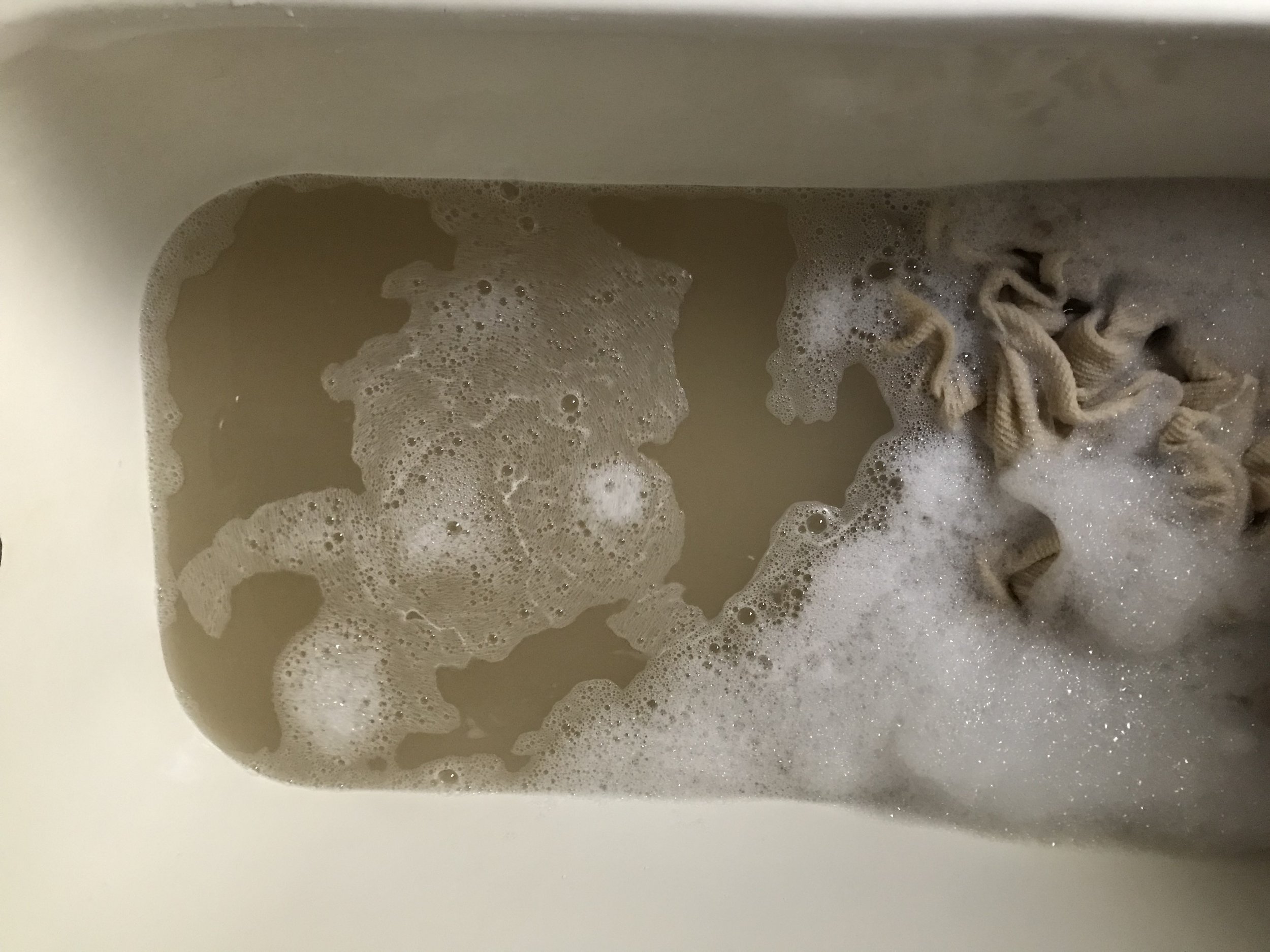

first go in the tub

That’s a wonky angle! I decided to go with plain old plant-based dish soap for this first set of washings. The fabric was as dirty as I thought.

-

second go

The water is pretty hot - not so hot it is uncomfortable for my hands, but not lukewarm. I just blobbed in a tablespoon or so of soap.

-

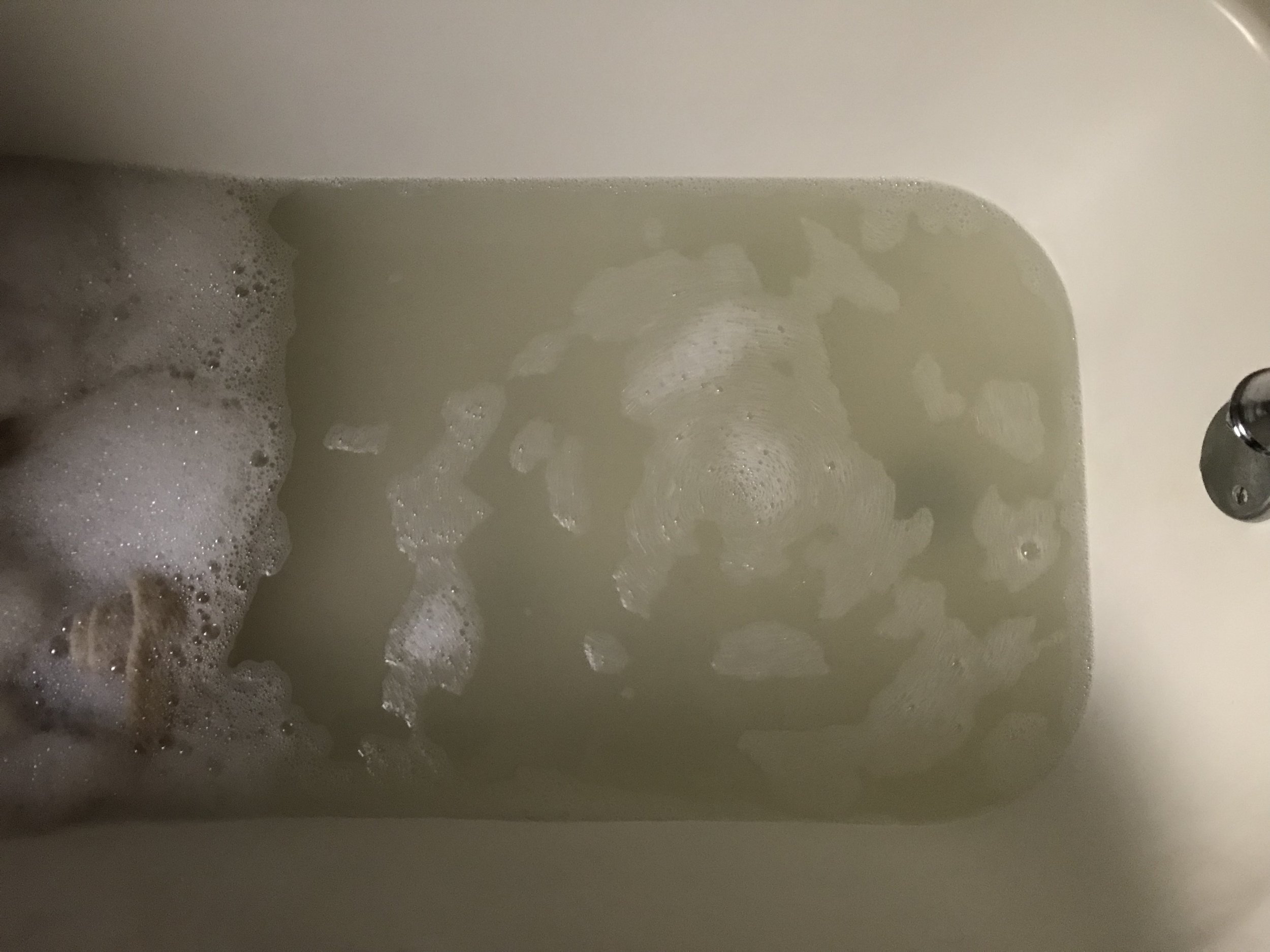

third go, seeing some progress

I think I’ll check the fabric after this rinse. It is definitely shrinking, and the weave is getting tighter.

-

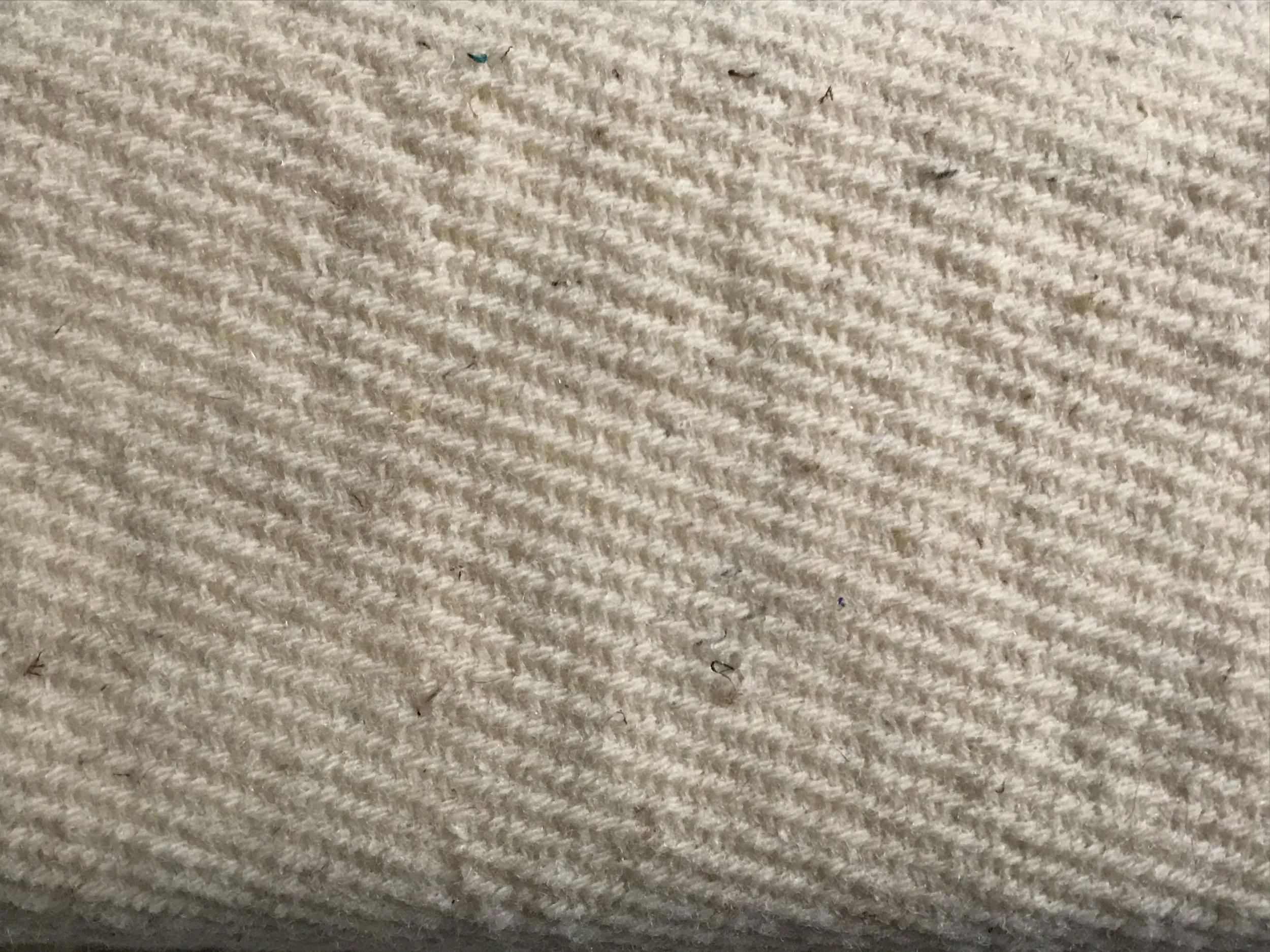

fulling happening

It’s much tighter, but look at all the little specks of vegetable matter - how am I going to get those out? Am I going to get those out?

-

fourth go

Oh, for consistent photography. This is looking (and smelling) much better. I think it is time for my friend to take a couple of rides in the washing machine.

-

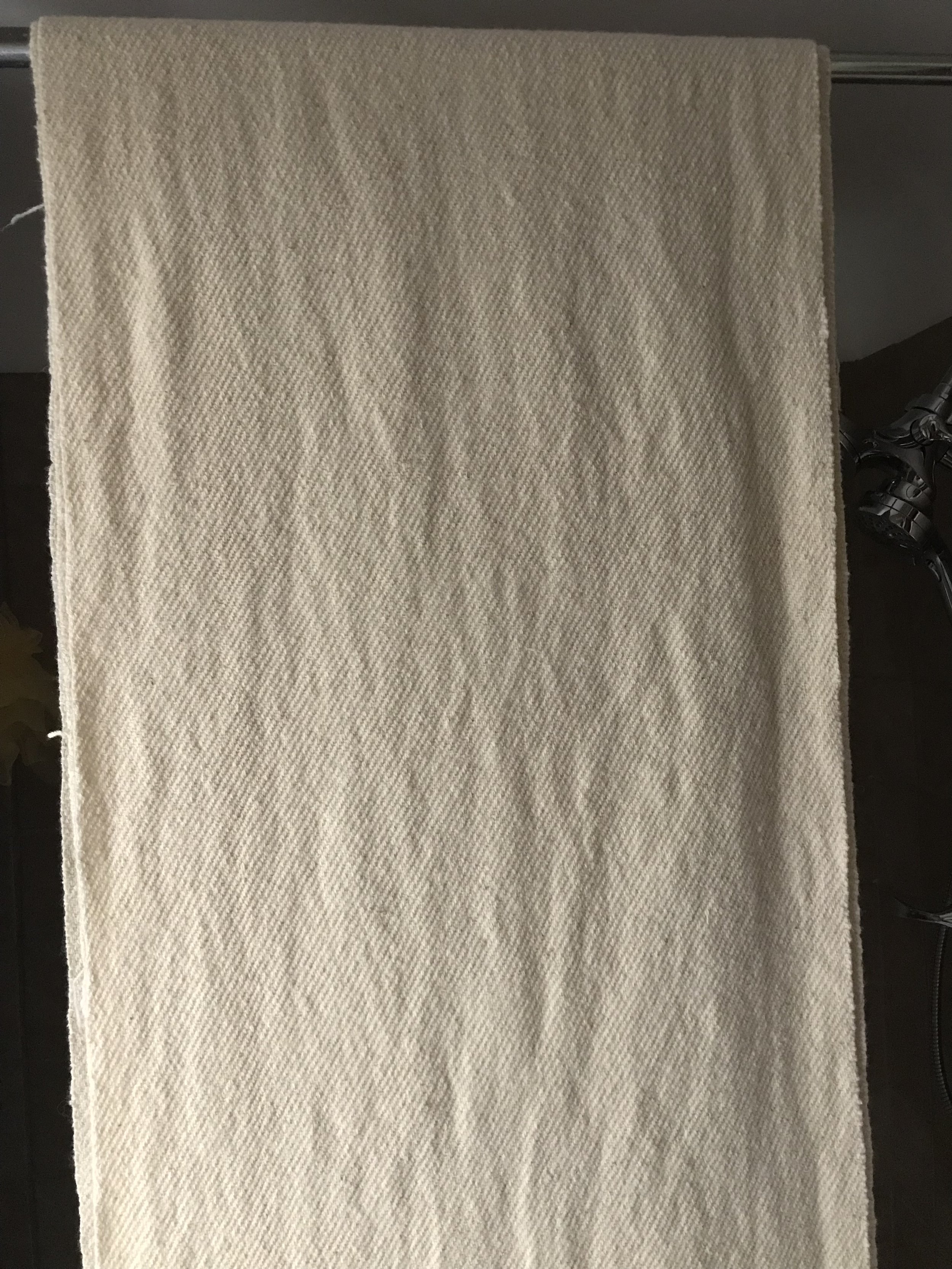

two rinses later

I have a front-loading washer and the rinse/drain cycle lasts for about 11 minutes. Two runs through that brought us to this pass. This fabric is quite thick, so I am no longer sure what I will make with it; maybe a waistcoat would work, or some thick pants.

-

a bit cleaner

More of the VM seems to be breaking up. So far, the fabric has shrunk from: Pre-Wash, 6 yds x 25”; Post-Wash, 5.5 yds x 21.25”. That’s pretty significant, a bit over 9% in length and almost 9% in width. I’d like it to show less of the weave; I suppose that that is where the teasing and shearing come in.

-

next step is dyeing

But it is mid-April and my dye plants are all still babies. This is a white aster that attempted to take over my backyard last year, with some success. It makes a soft yellow dye that goes gray-green when mordanted with iron. It might work?